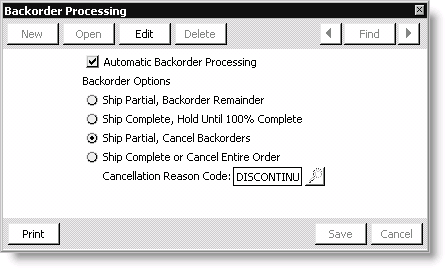

Backorder Processing window

Automatic Backorder Processing

Enable to release backorders automatically when you enter and post product inventory receipts.

Backorder Options

When you enable Automatic Backorder Processing, you have several Backorder Options that you can enable on the Backorder Processing window. The Backorder Options allow you to define specific parameters for how iMIS processes backorders:

Ship Partial, Backorder Remainder

The Ship Partial, Backorder Remainder option enables by default when you use Automatic Backorder Processing and is the most widely used backorder processing option. The Ship Partial, Backorder Remainder option performs the following backorder processing tasks when enabled:

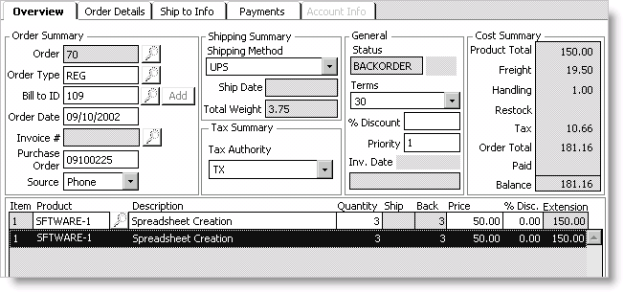

- Backorder Entire Order - When all of the products ordered are on backorder, iMIS automatically places the order in backorder status. When any ordered products become available through posted inventory receipts, the order is released from backorder status to the first processing stage for the given order type. If any of the ordered products remain on backorder, the order follows the processing steps for a partially shippable order.

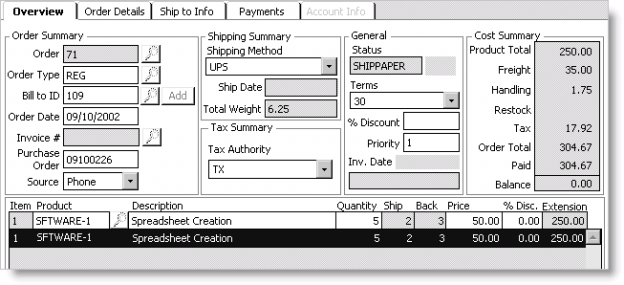

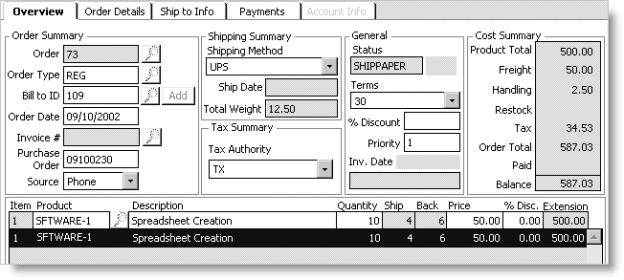

- Ship Partial Order - When some of the products ordered are on backorder, iMIS automatically places the order in the first processing stage for the given order type, such as PICKLIST, SHIPPAPER, or INVOICE, as with complete orders.

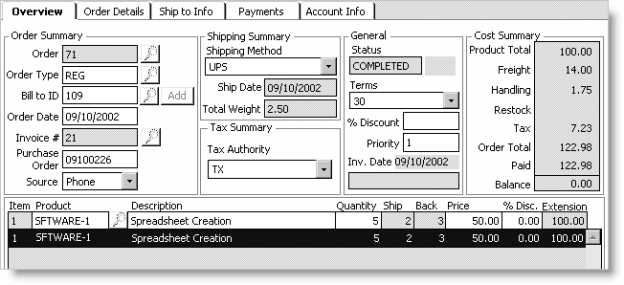

- iMIS recalculates the original order's product totals to include only the quantities actually shipped.

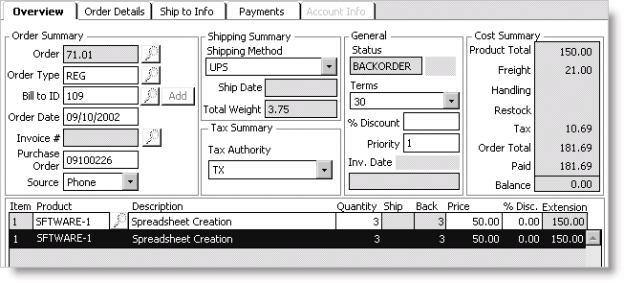

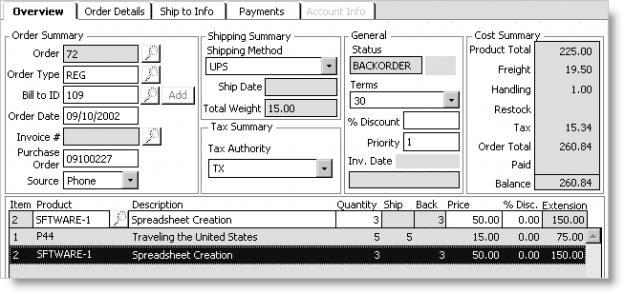

- iMIS generates an extended suborder, which is assigned the original order transaction number plus .01, such as 208.01. The extended suborder consists only of the backordered products remaining when the original order was invoiced. The original order retains the backordered product's product code with an Extension price of 0.00 as displayed on the Enter and edit orders window.

- Any prepaid cash amounts are split appropriately between the original order and the extended suborder. The original order's cash amount equals the lesser of the full cash amount or the invoiced total. All remaining cash applies to the extended suborder.

If one or more of the ordered products remain backordered when the order is invoiced, iMIS proceeds with the following steps during the invoicing stage:

Note: An extended suborder can continue to generate additional extended suborders for products that remain on backorder.

Ship Complete, Hold Until 100% Complete

If you enable the Ship Complete, Hold Until 100% Complete option, iMIS does not ship an order until all ordered products are available in inventory. Orders for products with insufficient inventory are placed on backorder whether or not the products are fully backordered or partially shippable. No extended suborders are generated because the order does not have any backordered quantities remaining when it is shipped and invoiced.

Ship Partial, Cancel Backorders

If you enable the Ship Partial, Cancel Backorders option, iMIS treats backorders as normal orders upon data entry. However, unlike complete and ship partial orders, you are prompted to cancel the backordered products (or the entire order if it is completely backordered) at the Invoice orders processing stage.

If you do not cancel the backordered products when invoicing the order, an extended suborder is generated for the backordered products. The original order then goes automatically to the first processing stage for the given order type, such as PICKLIST, SHIPPAPER, or INVOICE.

Ship Complete or Cancel Entire Order

If you enable the Ship Complete or Cancel Entire Order option, you can cancel partial or completely backordered orders at order entry. When an order is entered for any product on backorder, a message displays prompting you to cancel the order instead of generating a backorder. If you elect not to cancel the order, the order does not ship until all products are available in inventory just as if the Ship Complete, Hold Until 100% Complete option were enabled.

Cancellation Reason Code

(Displays when the Ship Partial, Cancel Backorders option is enabled) Enter a reason code for canceling orders. Select the Find icon to look up a cancellation reason code.

Cancellation reason codes are defined on the CANCELLATION general lookup/validation table (from Customers, select Set up tables > General lookup/validation).